On April 26, Batchfire Resources’ Callide Mine celebrated 80 years of operation, from humble beginnings in 1944 to now being one of Queensland’s safest, most efficient operations producing up to 11 million tonnes of ultra-low impurity coal each year.

“To have operated continually for 80 years is a tremendous achievement for Callide Mine, both under the management of Batchfire Resources and the previous responsible owners of this productive operation,” said Batchfire Resources CEO Allan Fidock.

“At a time when coal was considered to be of low value, early pioneers like the Thiess Brothers saw value where others didn’t, understanding that the energy needs of Queensland would require a solution like Callide Mine’s thermal coal.

“We continue to focus on powering Queensland industry and homes, while also supporting and caring for the local community, First Nations Gaangalu People, and of course the land on which we operate – taking Callide Mine into the future,” he said.

To acknowledge the occasion and recognise the support of those who choose to work at the mine, Batchfire Resources is hosting a Family Day in September.

“We acknowledge the importance of 80 years of Callide Mine by coming together within the community responsible for so much of the mine’s success,” said General Manager Operations, Scott Haynes.

“Around 85 per cent of our workforce resides within the Callide Valley and always has, so we want to take the opportunity to acknowledge the families behind the scenes that support their family members who are responsible for keeping around 15 to 18% of the lights on across Queensland.

“By welcoming family members for the day, it gives children, partners and even parents a look at the impressive machinery, technology and teams that make it happen at Callide Mine.”

The anniversary also coincides with another momentous occasion – the 100th anniversary of the Biloela township. Batchfire Resources is contributing to the celebrations throughout Biloela, joining locals in celebrating the thriving community.

80 YEARS OF HISTORY

The story of Callide Mine started in the 1890s when a seam of ‘black gold’ was discovered by three state-aided prospectors – at a time when coal was worth less than a dollar per tonne.

Until the coal was discovered, gold fossickers scoured the Callide Valley in search of a precious-metal payday, with moderate success. Gold fever throughout the region remained into the 1900s, but there was an equally valuable resource right under the noses of fossickers.

In 1891, Government Geologist William Rands sunk six shafts at the site, which would become Callide Mine, to reveal a 9 metre thick coal seam that was one of the largest in Australia at the time.

However, some 30 years passed as the forgotten treasure remained untouched, with cattle grazing on the scrub around Dunn Creek and Petersen’s Gully and people unaware of how valuable the land on which they roamed would become.

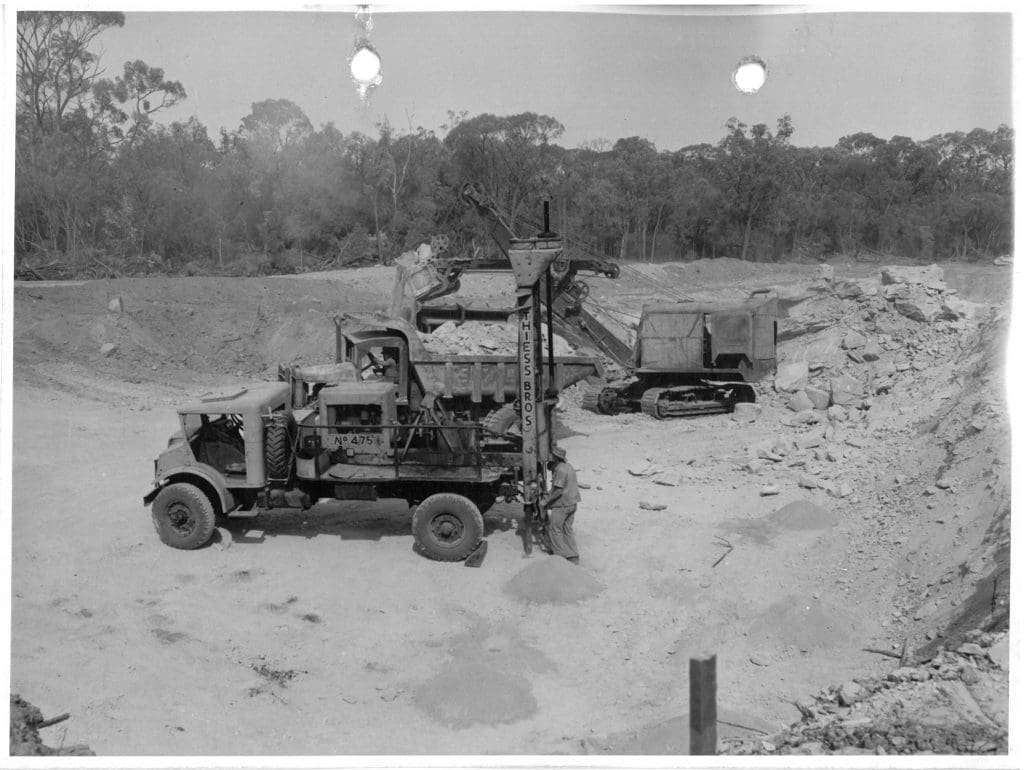

In those days, coal was used primarily to power steam trains and was deemed to be of little value compared with more desirable resources like gold, but early pioneers saw its value as a commodity of the future. Those innovators were none other than the iconic Thiess Brothers, who were commissioned to remove overburden for the new open-cut coal endeavor when a second head of steam and need emerged.

The Thiess Brothers took the hand-dug mining operation, which relied on horse-and-cart transport, into the future with a fleet of high-productivity machinery. A major post-WWII machinery shortage required the enterprising Thiess Brothers to look further afield in their search for the biggest machinery they could get their hands on, heading to the jungles of Papua New Guinea to buy abandoned war-time machinery ‘by the acre.’ Much of the machinery was rusted beyond repair, but mechanical genius Cecil Thiess restored and modified the equipment – which would ultimately shape the way we mine today.

On April 26, 1944, Thiess Brothers began excavations at Callide Mine using a single D7 tractor and ripper to move 2400 cubic yards of overburden in just four days, exposing one of the best seams of black gold.

Before long, the D7 was joined by a fleet of new-age machinery, trucks and equipment that were responsible for extracting and transporting the coal to the nearby port town of Gladstone for domestic and international customers.

By the 1960s, a 25-year contract with nearby Calcap Power Station (now decommissioned Callide A) would open the door to lasting prosperity for the Callide Mine at a time when the operation had a staff of just 23 men.

Another jewel in the crown for the mine was a 22-year contract with Callide B power station that landed in 1988, which led to a major increase in staff and the need to look ‘to the future’ to remain competitive as a leading energy supplier into the twenty-first century.

In 1993, Callide was taken to another level, with an $80 million investment in the state-of-the-art Marion 8750 dragline, which is still operating today. The Marion 8750 was the largest dragline in Australia at the time, with a 128-metre boom, 80 cubic metre bucket and the capacity to move 20 million cubic metres of overburden each year.

Batchfire Resources purchased the mine on 1 November 2016 and remains committed to supporting the local economy and its people, keeping the lights on in homes and businesses across Queensland and shaping the state as we know it.