Stephen Wallace has spent over two decades in the glass industry, drawing on his deep expertise to develop ArdGard – an innovative product designed to address the dangers posed by glass in heavy machinery.

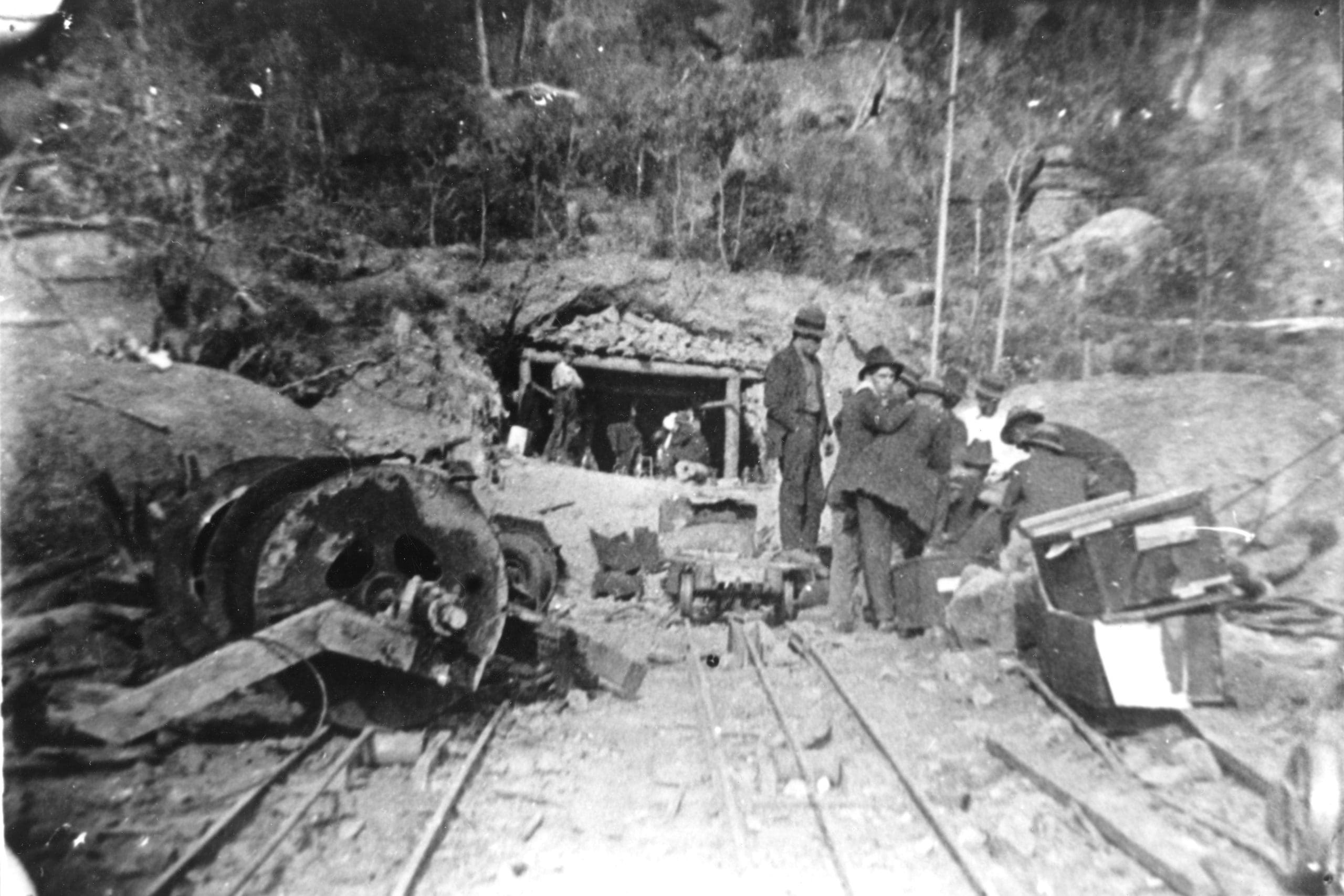

After moving to Dysart fourteen years ago, Stephen started Ardik Glass, a family-run business focused on replacing glass on mine-site machinery.

“Over the years, I’ve seen firsthand the risks operators face when glass shatters or is damaged,” said Stephen.

“In a close-knit community like Dysart, every incident makes everyone uneasy as we wait to hear if someone we know has been affected.”

Throughout his career, Stephen has encountered numerous incidents involving shattered glass, some of which could have been avoided with better materials.

“I’ve seen everything from toughened glass shattering into tiny pieces to overloaded loader buckets causing rocks to fall onto windshields, endangering operators.”

During an audit on a mine site, Steven discovered inconsistencies in the types of glass used. While some machines were fitted with appropriate safety glass, others were equipped with 6.76mm laminated glass, no thicker than a standard car windscreen and an unsuitable choice for heavy machinery in certain locations on the mine site.

“This glass was never intended for high-impact environments, like dozers working next to high walls where there is a greater possibility of impacts from falling rocks.

“A thicker, more impact-resistant glass should have been used, as the 6.76mm laminated glass cannot withstand the kind of stress loaders and dozers experience on site.”

Motivated by the need for improved safety, Stephen set out to create a better solution.

“After years of effort, we’ve developed ArdGard, a world-first safety innovation specifically designed for stockpile dozers and other high-risk environments.

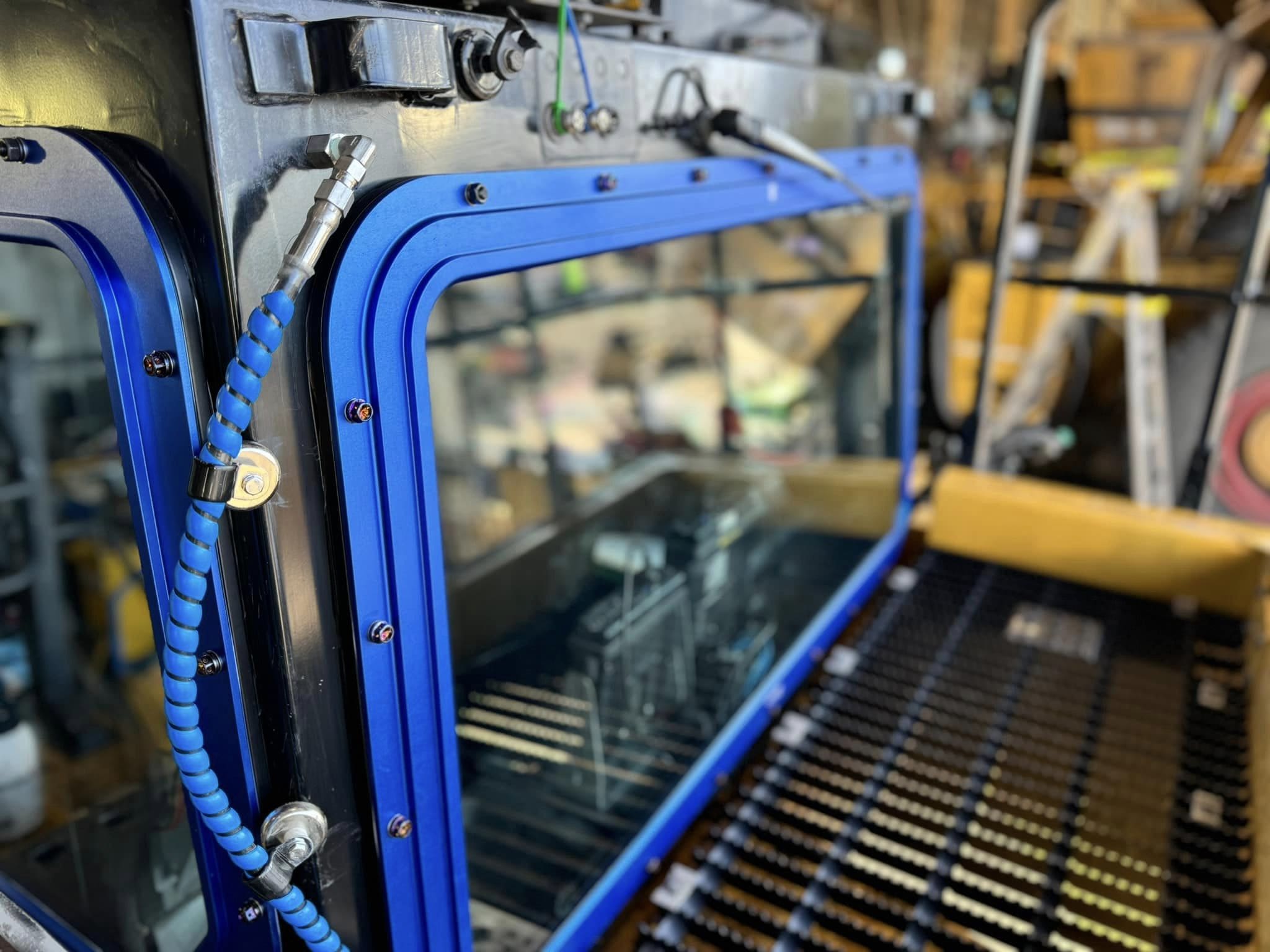

The ArdGard quick-fit framing system allows operators to swap out damaged polycarbonate panels without needing a glazier, minimising downtime. The framing system also includes 6.76mm WHP safety glass as a sacrificial layer to protect the polycarbonate beneath. This layer absorbs everyday wear and tear, reducing the need for frequent polycarbonate replacements.

“Polycarbonate is virtually unbreakable, and with recent advancements, we’ve made it as optically clear and warp-free as glass. It can even withstand the 40 psi pressure standard required for mining operations.”

Stockpile dozers face a unique hazard: air pockets forming beneath coal. When these pockets collapse, the dozer can be engulfed. Traditional glass makes operator retrieval difficult, as it’s glued directly to the machine and often requires cutting to access the cab.

“ArdGard’s frame system solves that issue with quick-release mechanisms. In the event of an emergency, the frame can be unbolted in minutes, allowing for rapid operator evacuation.”

Toughened glass is also difficult to replace on-site, often causing costly downtime as specialised pieces are ordered and shipped. In contrast, ArdGard offers easy replacements with standard tools and locally available materials.

Reflecting on the industry, Stephen points out the gap between technological advancements and operator safety.

“With all the innovation around automation, it’s surprising how little attention is given to improving safety glass in heavy machinery.

“It’s baffling that machines worth millions can be grounded by something as small as a broken windshield.”

ArdGard offers a new standard – one that emphasises operator safety, quick repairs and reliable materials, ensuring that mining operations can run efficiently without compromising safety.

Although ArdGard was initially designed for stockpile dozers, the versatile frame can be adapted for use across other machinery types.

Steven said the feedback has been incredible and BMA is currently trialling two full kit-outs at Saraji Mine with the focus on improving operator safety and preventing downtime caused by glass damage.

“I’m really excited about where this product can go. We’re eager to trial ArdGard on more sites and explore its potential across different mining environments.”